The entire set of equipment for the UDS motor ship was delivered to the ÖSWAG shipyard

A set of new equipment for the vessel “Captain Antipov” was delivered to the Austrian shipyard.

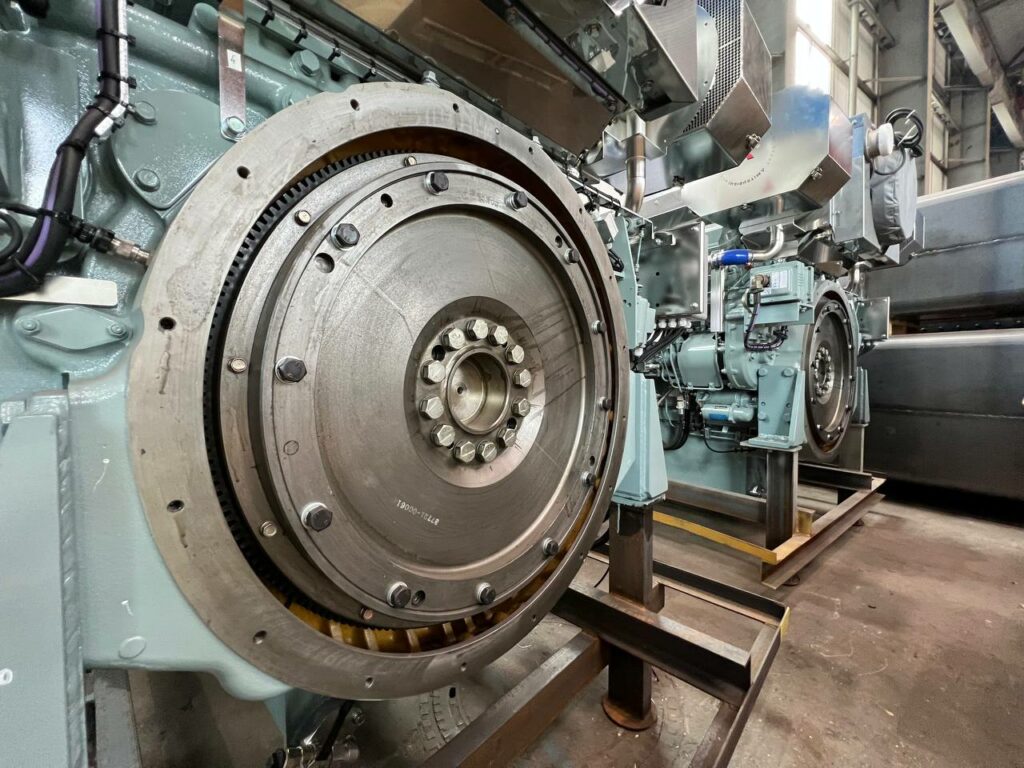

“Main engines, diesel generators, reducers, control system, cooling and much more,” reported the press service of the Ukrainian Danube Shipping Company.

In particular, an exhaust gas cleaning system was delivered to the ÖSWAG shipyard.

“All equipment from leading manufacturers. With a large resource. The locomotive is more than 40 years old, with the new “filling” the ship “Captain Antipov” will work for the same amount of time,” the UDS emphasizes.

As a result of modernization:

1. The efficiency of using the vessel will increase threefold. After all, we replace equipment that accounts for approximately 95% of malfunctions. The locomotive, which usually spent 70-80% of its working time in downtime and repairs, will finally start to work and make a profit.

2. Flight time will be reduced by up to 30% – with new, more powerful engines, speed and maneuverability will increase.

3. The number of crew members required to ensure the operation of engines and other systems will decrease.

4. The vessel will meet modern environmental requirements, which opens up the possibility (under certain conditions) of entering the Rhine river transport market.