The most-most port of Pivdenny: from Hammer to the present day

Pivdenny seaport is one of the youngest ports in the country, which is the deepest in Ukraine; occupies a strategic position in the work of international transcontinental transport corridors and is the most promising for ensuring the interests of Ukraine as a transit state. In the water area of the port, the Odessa Port Plant, the largest in Ukraine state-owned bulk cargo stevedore Yuzhny Port, the TIS group of companies and other stevedore complexes operate.

In this article, we have collected the most interesting facts about the development of the port water area from the moment of its creation to the present day.

To begin with, in order to avoid confusion in the presentation of the material, let’s clarify the history of renaming the port and water area. In 2013, as a result of the reform of the maritime industry, the State Enterprise “Ukrainian Sea Ports Authority” was created, and the port of Yuzhny itself, as a single complex, was accordingly divided into the port administration, which, within the entire water area, is engaged in ensuring safe navigation, operating berths on its balance sheet, and the collection of port dues, as well as the stevedoring company SE MTP “Yuzhny”, which is engaged in the transshipment of bulk cargo on the eastern coast of the Adzhalyk Estuary (old. Maly Adzhalyk). In 2019, regarding the “decommunization and de-Russification of Ukrainian seaports”, the Ministry of Infrastructure of Ukraine initiated the renaming of Yuzhny seaport, as a geographical concept, into the Pivdenny port, which entailed a change in the name of the branch of the Administration of seaports, and the old name Yuzhny was preserved only by the state stevedore enterprise. The reason why the state stevedoring company did not change its name, within the framework of de-Russification, is not known for sure, but, most likely, we are talking about saving funds associated with re-registration (unlike Yuzhny, during a similar renaming of the port of Illichivsk, after the branch of the USPA, the state stevedore also changed its name to Chornomorsk).

Also in the water area of the port operates the state oil terminal of the same name MOT “Pivdenny”. We hope that when it comes to changing the name of the state stevedoring company, a competition will be carried out for the best new version of the name, different from the name of the port as a whole.

Above: a lay out of the port of Pivdenny

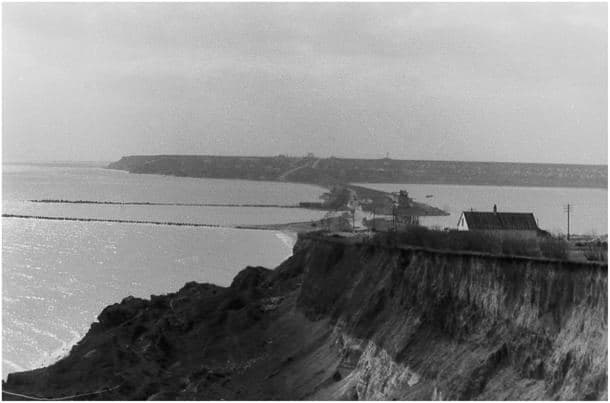

Like the Sukhoi Estuary (where the port of Chornomorsk is now located), the Adjalyk Estuary was originally separated from the sea by a sand bar. In the late 1940s, the estuary began to connect with the sea by constructing two breakwaters – 350 and 370 meters long – in order to transport the stone mined in quarries in the area of the Buldynki village by barges. Residents of neighboring villages worked. They erected breakwaters (dams), hammered wooden piles, laid the space between them with granite, which was delivered by train to Odesa, and from there they were brought by cars to Grigorievka, to the construction site. The stone was laid, sprinkling it with sand and gravel. By the mid-1950s, the “stone-wooden” dams had been erected, albeit not completely.

Dam 1950

The dams were built, but there were neither funds nor opportunities to deepen the shallow shores of the estuary, and in general, the work, which had already absorbed several million rubles, was carried out very slowly. Simultaneously with the construction of breakwaters, since 1950, the construction of a road from the Buldynsky plant to the Mykolaiv highway was carried out. It began in Grigorievka and ended at Buldynsky plant. In 1954, the road was ready, and the construction of the port was stopped on January 1st, 1955. However, according to fragmentary information, one barge nevertheless entered the estuary behind the stone.

The beginning of the berth № 6. Port fleet

Filling the berth № 5 with sand

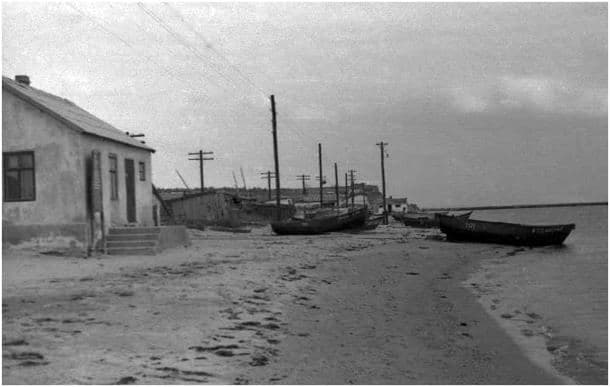

Around the end of the 1960s, regarding the onset of the sea, along the very shore of which a section of the Reni – Rostov route passed, a fundamental embankment was erected with a large solid (over 100 meters long and up to 8 meters high) bridge. Fishing boats were based on a rather narrow sandy embankment separating the estuary from the sea. The beautiful steep banks of the estuary are completely overgrown with bushes of wild rose, hawthorn, blackthorn and blackberry. At the very beginning of the 1960s, there were talks about the construction of rest houses and mud baths in the Grigoryevka area, which were supposed to use the local therapeutic mud of the Maly Adjalyk Estuary. Their properties were not inferior to the famous Kuyalnik muds. It did not take place. All this is “buried” now under the cargoes of the sand complex of the port of Yuzhny.

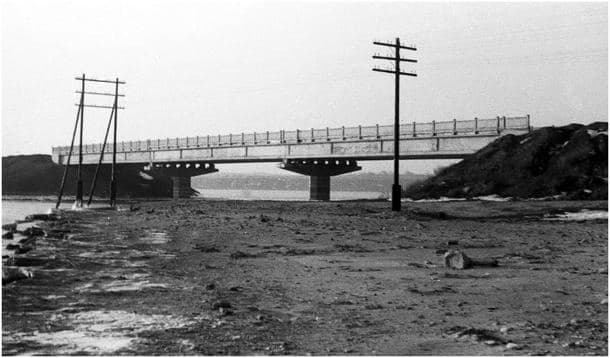

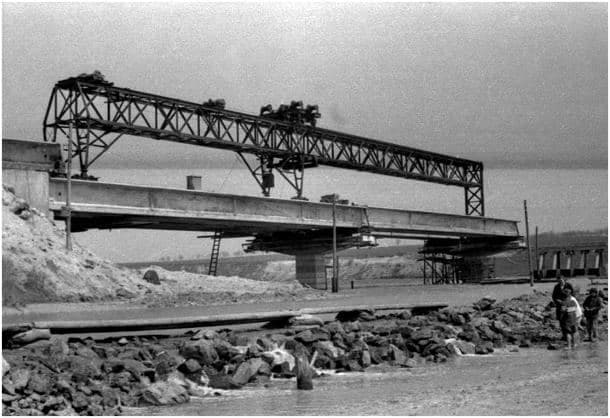

Sand Spit Bridge

Grigorievka was located in a very convenient and beautiful place on the seashore and estuary, rich in fish. But when in 1971, in connection with the beginning of the construction of the port of Yuzhny, the closed estuary was connected to the sea, most of the fish left. There was a village council in the village, there were three shops, a cafe (at first it was called Chaynaya, and later – Grot) and a warehouse. A warehouse is a large refrigerator, in modern terms. There were no refrigerators in it at all. A large rectangular room was adjoined by a round extension, the roof of which consisted of a thick layer of reeds. After all, the reed, hollow inside, was a kind of thermal insulator. This room was called “glacier”. In winter, it was filled to the brim with ice sprayed on the estuary, the thickness of which in those cold winters reached 80 centimeters. The reserves of this ice, which were poured over the brought fish, were sufficient until the next winter. There was a wooden pile berth near the storage shed, where fishermen brought their catches. Then seiners came to the raid, bringing the selected Black Sea mackerel.

Sand spit

The construction of the port was carried out on the territory of the village of Grigorievka, which was demolished in the same way as the village on the other, eastern bank of the estuary – Starye Belyary. Until 1978, the port had the working name Grigorievsky. The territory on which the construction began has an incredibly interesting history: archaeologists, having begun excavations in the area of the village of Voronovka, discovered an ancient settlement of the Bronze Age (II millennium BC). And at the entrance to the port, they found an ancient mound with 34 layers of burials, at the very bottom of which there was a stone tomb.

The construction of the port began in 1973 and proceeded in parallel with the construction of the Odesa Port Plant, in the creation of which the American multimillionaire Armand Hammer invested.

Interesting fact

Armand Hammer was born in 1898 in New York. His grandfather Yakov was the son of a wealthy Kherson shipbuilder. He inherited the family business when he was still a child, and his relatives were in charge of the family business. In 1875, the entire family emigrated to the United States. Armand’s father, Julius was a gynecologist by training. In addition to his specialty work, he owned a small network of five pharmacies in the United States. Julius was a communist, he personally knew Lenin and Trotsky, and was also one of the founders of the American Communist Party.

Armand followed in his father’s footsteps, graduating from Columbia College Medical School in 1919 and Columbia University in 1921. However, Armand never worked in his specialty. In 1919, Julius Hammer performed a surgical abortion, which ended in patient`s death. In 1920 he was sentenced to 2.5 years in prison.

It is believed that the illegal operation was carried out by Armand, and his father took the blame. It is true, that the harsh sentence was associated with membership in the Communist Party, which was not favored in capitalist America.

The family business fell into the hands of Armand. Simple daily operations were of little interest to him. In 1920, the US government announced Prohibition. This opened up great business opportunities, and Hammer was quick to seize them. In his pharmacies, ginger alcohol tincture appeared as a cure for sore throat. For a year in this business, Hammer earned $ 1 million.

At that time, the USSR attracted his attention. Armand’s father was friends with Ludwig Martens, the unofficial representative of the USSR in the United States. Taking advantage of his connections, Hammer went to Moscow with the hope of negotiating the sale of drugs in the USSR. He himself claimed that he went to the USSR to treat typhus patients and hoped to return the $150 thousand owed to his father’s company for medicines and oil equipment.

In Moscow, the American businessman was generally received amiably. After assessing the circumstances within the country, Hammer decided that the focus should not be on medicines, but on food. The first deal he made was the exchange of a million bushels (27,216 tons) of wheat for caviar, furs and jewelry expropriated by the Soviet state.

Upon his return to the United States, Hammer managed to become the representative of 38 American companies in the USSR. One of the main successes of the entrepreneur was the conclusion of an agreement with Henry Ford. The USSR needed tractors and cars, and Ford could help with this. Hammer was fortunate that Ford’s Fordson tractor division was still unprofitable at the time, and, as Ford himself argued, could only start to make a profit if its sales reached thousands of units a day.

Hammer, in turn, offered Ford a huge market and the ability to reach that target faster. During the negotiations, the entrepreneur also noted that the USSR lacks qualified engineers, and made it possible for several young Russian engineers to travel to the Ford plant to study working methods. He set the same condition in agreements with other American companies.

The transactions carried out were profitable, and, given the loyalty of the Soviet leadership, in the USSR the entrepreneur had much more opportunities to further develop his business. That is why Hammer moved to the Soviet Union soon. His institutions began to appear not only in the USA and the USSR, but also in the countries adjacent to the republic.

In the USSR, Hammer’s activities developed no less than beyond its borders. In 1921, Hammer received a 25-year concession to mine asbestos in the Urals. Lenin himself offered it to Armand during their first conversation. For four years this business did not bring profit due to falling prices in the world market. But since 1925, things have gone smoothly.

Armand Hammer died at the age of 92. Throughout his life, he managed to vary between different countries and politicians, which had an impact – Armand was one of the richest entrepreneurs in the world. Nevertheless, due to vanity and waste at the time of his death, he had more debts than fortunes – the heirs did not receive a cent.

Armand Hammer

ODESSA PORT PLANT

In February 1975, the first pile was driven into the future berth № 3. It became the first berth built (the one is known as “ammonia berth”).

On July 27, 1978, this berth received the first vessel – the Latvian gas carrier “Bulduri” of the Latvian Shipping Company. The first in the history of the OPP and the port, the loading of a gas carrier lasted almost two days, 8 thousand tons of ammonia were loaded. The gas carrier opened the line port Yuzhny – ports of Italy (Marghera). Since then, the port workers have considered July 27 to be the birthday of their enterprise.

Gas carrier Bulduri

During the period from 1978 to 1983, almost 6 million tons of ammonia, 2 million tons of superphosphoric acid, 4.5 million tons of urea and tens of thousands of tons of other cargoes passed through the port’s berths.

In 1979, the Togliatti – Odessa ammonia pipeline was put into operation. It is the longest ammonia pipeline in the world to date.

The total length is 2,417 km, of which 1,018 km pass through Ukraine. The branch, which carries ammonia from Togliatti (ToAz), has a length of 804 km. The operator serving the Ukrainian part of the ammonia pipeline is the State Enterprise “Ukrhimtransammiak”, the Russian part is served by “Transammiak” OJSC. The cost of transporting ammonia through the Togliatti – Odessa pipeline has always been a reason for disputes between the economic entities of the two countries. The objective reason is that this is the only ammonia trunk pipeline of this scale in the world. The second, which is much more modest, operates in the United States.

Interesting fact. Until the end of 2006, the tariff for pumping ammonia remained unchanged at $ 2 per tonne per 100 km of ammonia pipeline, later it increased several times – in 2007 and 2011. The maximum tariff was $ 4.8 per tonne per 100 km. the path was established by the Ministry of Economic Development of Ukraine in October 2015, but a year later the Supreme Administrative Court of Ukraine considered the claim of PJSC TogliattiAzot (RF) and declared the corresponding increase as illegal. As a result, the tariff was reduced to the previous level – $ 3.8 per tonne per 100 km.

It should be noted that, along with the pumping tariff, the rate of rent for the transportation of ammonia also grew – from 1 to 2.4 USD per tonne per 100 km. However, after the last decrease in the transit price, the rental rate remained at the same level.

However, at the end of 2019, State Enterprise Ukrhimtransammiak won an arbitration in the International Commercial Arbitration Court against PJSC TogliattiAzot in the amount of more than $ 190 million.

Port in port (group of TIS terminals).

TIS-Fertilizers LLC – bulk chemical cargo, grain cargo and processed products of the oil extraction complex.

TIS-Grain LLC – grain cargoes, processed products of the oil extraction complex.

TIS-Ore LLC – IOC (iron ore concentrate), steel pellets, oil.

TIS-Coal LLC – bulk cargo, oil.

TIS-Container Terminal LLC – containers, oil, metal, bulk cargo

M.V. Cargo LLC – grain cargo.

TIS

In September 1994, 22 kilometers from Odessa, in the water area of the Maly Adjalyk estuary, a new company, Transinvestservice (TIS), was launched.

Then, on that place, there was an abandoned transshipment complex for the import of phosphorites. It had been built in the late 80s, but only the first stage was put into operation. The abandoned construction site could hardly be called a port: the complex included one warehouse, a berth and a part of the railway. The founders of TIS Alexei Stavnitser and his partner Oleg Kutateladze saw a perspective in this place. The investors decided to revive the project by changing the profile of the complex from import to export.

This is how one of the first TIS terminals for transshipment of mineral fertilizers appeared.

TIS-Fertilizers

Already in 1997, TIS-Fertilizers processed the first million tons, transshipping products from all over the former Soviet community. Largely thanks to the terminal, this type of cargo began to be exported massively all over the world.

In total, TIS investments in the development of its terminal in the port of Pivdenny in 2018 amounted to almost $ 700 million.

The private terminal complex, which was gradually created in the water area of Yuzhny port, has turned into a diversified logistics hub. Today the group includes five terminals spread over 400 hectares of land: TIS-fertilizers (opened in 1998), TIS-Grain (in 2000), TIS-Ore (in 2004), TIS-Coal (berths № 19 and 20 opened in 2007), TIS-Container Terminal (built in 2009) and, in fact, TIS itself, which ensures the functioning of the entire infrastructure.

In 2000, the TIS-Grain terminal was opened: the largest grain terminal in the Black Sea. One of three large private stevedoring terminals providing a significant share of all grain exports in Ukraine. The founder and owner of 100% of the shares is a Hungarian citizen Aleksey Fedorich. The terminal occupies a land plot of 14 hectares. Cargo transshipment is carried out through the modernized berth №16 (length – 279 m, depth at the line – 14 m).

TIS-Grain

In 2004, the TIS-Ore terminal was launched – the largest and most efficient export terminal for transshipment of steel pellets, which is a strategic link in the export logistics of Ferrexpo, the company is a co-owner of the terminal.

TIS-Ore

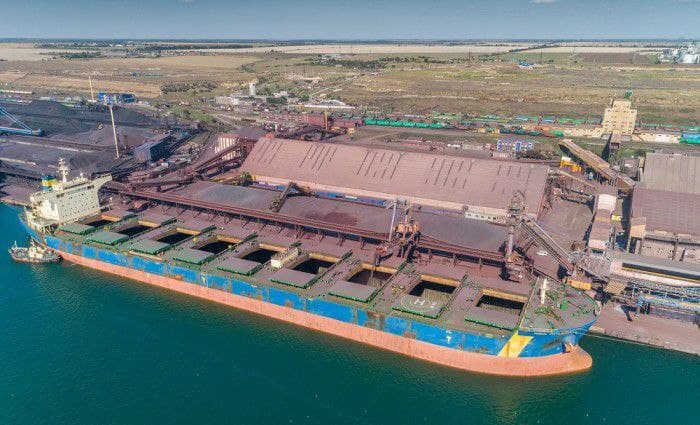

In 2007, TIS-Coal, the largest coal-ore terminal in Ukraine, was opened. It is capable of receiving vessels with a deadweight of over 200 thousand tons. Holder of the absolute record for the loading speed of vessels in the Black Sea – 107 thousand tons per day.

TIS-Coal

TIS-Container Terminal (2009) – the deepest container terminal in Ukraine, winner of the “Best Service” nomination from the Association of International Freight Forwarders of Ukraine. In 2017, the total cargo turnover of the terminal amounted to 3.5 million tons, which is 50% more than last year. Transshipment of containers per TEU in 2016 increased by 51%, making an annual record among the ports of Ukraine.

TIS-CT

Dredging TIS-CT

In 2020, TIS attracted a global investor – DP World: in June, the companies announced the completion of the transaction to acquire DP World a controlling stake – 51% of the shares of the TIS container terminal. In the first half of 2020, TIS handled 17.4 million tons of cargo, increasing cargo turnover by 21.6%. Since its inception, TIS has attracted more than $ 770 million in investments.

MV Cargo project (also known as Neptune grain terminal)

View of the Greenfield site, where MV Cargo is now located

MV Cargo

In August 2015, the American commodity trader Cargill, MV Cargo and the State Enterprise Ukrainian Sea Ports Authority (USPA) signed a tripartite memorandum of intent to implement an investment project for the construction of a grain terminal in Yuzhny port with a capacity of 5 million tons. Within the framework of the project, MV Cargo is building an onshore terminal complex, the USPA ensures the creation of a navigable operating water area of berth № 25 and a navigable approach channel to berth № 25. The memorandum states Cargill’s intention to acquire 51% of the terminal.

In June 2018, the grain terminal Neptune, a joint project of M.V. Cargo LLC with the largest American corporation Cargill. Owned by the company M.V. Cargo there are berth № 25 in Yuzhny port and land plots where the terminal’s facilities are located.

The construction of the terminal has become the largest investment project in Ukraine, with a total cost of $ 150 million. The project was financed by the EBRD, the International Finance Corporation (IFC) and local investors. The total loan amount from the EBRD and the IFC was $ 74 million.

Beau-rivage- Beautiful Bank (translated from French)

In 2009, the Borivazh grain handling complex was opened.

The terminal is located in the village of Novye Belyary and operates its own berth № 34 on the western shore of the Adzhalyk estuary of Pivdenny port.

The capacity of one-time storage of grain is 126 thousand tons. The annual transshipment volume is 1 million 864 thousand tons (data of 2019).

Borivazh, 2009

OIL HUB (PORT PLANTS AND EDIBLE OIL TERMINALS)

In 2011, Allseeds Group, one of the largest independent traders of unrefined sunflower oil, began operating in the water area, with a trade volume of 250 thousand tons achieved in the first year of operation. In 2013, the Allseeds Black Sea vegetable oil terminal was commissioned with a one-time storage volume of 42 thousand tons. At the moment, the terminal’s one-time storage capacity has been increased to 107 thousand tons with an annual transshipment of about 1 million tons of oils per year to sea vessels.

Allseeds Group

2013-2015 – construction and commissioning of an oil extraction plant in Yuzhny port. Due to its favorable location, the complex is capable of loading vessels with a carrying capacity of up to 100 thousand tons and a draft of up to 15 meters. The capacity of the new plant is 2400 tons of sunflower seeds per day or 1800 tons of rapeseed or 1500 tons of soybeans. The storage capacity of the elevator is 46,000 tons.

Oil extraction plant in the port of Yuzhny

At the end of 2012, the company RISOIL S.A. began construction of a new terminal for transshipment of vegetable oils in the city of Yuzhny, Odesa region. Is one of the largest exporters of crude sunflower oil and processed sunflower by-products from Ukraine. In 2013, the Risoil South terminal was commissioned.

Terminal “Risoil South”

Interesting fact.

It should be noted that both the Allseeds Black Sea terminal and the Risoil South terminal are technologically connected by a system of oil pipelines and carry out transshipment through the berths of the TIS group of companies, and there is a possibility of simultaneous loading of both terminals on one vessel. At the moment, 5 berths of the TIS group – 18, 19, 20, 21, 22 are equipped with cargo lines for loading tankers. In the near future TIS plans to build a pallet berth № 23 exclusively for transshipment of sunflower oil.

2014. Delta Wilmar CIS company, which is engaged in the production of oils and fats, begins its work on the territory of the port. The founder is Wilmar International Limited, headquartered in Singapore.

The Delta Wilmar Ukraine group of companies together with its partner companies make up a vertically integrated production system – from raw materials processing to finished product sales. The structure of the company includes two plants – one for the processing of tropical oils, the other for the processing of oilseeds, as well as a complex for transshipment of vegetable oils in Pivdenny port.

The Delta Wilmar Ukraine silo with the capacity of one-time storage – 30 thousand tons of sunflower, is located on the territory of the oil extraction plant. Acceptance of raw materials is carried out around the clock. It is also worth to say that the terminal of the company is connected by a technological pipeline with a length of more than 2.5 km with berth № 4.

According to USDA estimates, in 2019/20 MY Ukraine produced 7.05 million tons of sunflower oil (refined and unrefined). Delta Wilmar Ukraine’s share of the total volume of refined oil was approximately 299 thousand tons. Unrefined oil – 180 thousand tons.

In 2020, the Delta Wilmar Ukraine company launched a new technological line for filling oil into PET bottles. It is noted that in fact this is a separate workshop for bottling oil under the Chumak trademark. Investments in the workshop amounted to more than $ 5.5 million.

Delta Wilmar Ukraine

State Enterprise “Yuzhny Sea Port”

Marine Trade Port “Yuzhny” is the №1 state-owned stevedoring company in Ukraine in terms of cargo transshipment volumes. Every year, the SE handles about 13 million tons of bulk and general cargo (iron ore raw materials, coking and thermal coal, metal products, leguminous cargo and products of their processing). The port operates 5 berths:

Berth № 5: construction years 1981 – 1985;

Berth № 6: 1981-85;

Berth № 7: 1999 – 2000;

Berth № 8: 2004;

Berth № 9: December 2009.

(Data provided by the Institute “Chernomorniiproekt”).

Marine Trade Port “Yuzhny” handled 18.8 million tons of cargo in 2020. This is the maximum indicator in the entire history of the enterprise, which is 24% higher than the previous record.

Export ore processing increased by 4.8 million tonnes (+ 53% compared to 2019) to 13.7 million tonnes. The growth in the transshipment of export cargo is 47% compared to last year.

According to the press service, the state stevedore processed 6 vessels with components for wind generators: columns, gondolas, hubs, drives and blades, which were handled by the enterprise for the first time. Before unloading the blades, a global preparation was carried out: the expansion of roads, the preparation of warehouses, and a technology for handling oversized cargo was developed.

During 2020, Marine Trade Port “Yuzhny” handled 330 vessels, including 154 Capesize vessels. The number of vessel calls is 36% higher than last year’s result. 257,010 gondola cars were handled by the staff of the state stevedore in 2020. This figure is 19% higher than last year.

In May 2020, Marine Trade Port “Yuzhny” increased its monthly cargo transshipment to a record 2,100,000 tons. This is a new historical maximum in the entire history of the port since 1978. The State Stevedore confidently maintains its leadership position and successfully updates cargo handling technologies and modernizes production.

SE MTP “Yuzhny “

OIL GATES (TERMINALS FOR TRANSFERRING OIL AND PETROLEUM PRODUCTS)

MOT PIVDENNY In 2001, the Odesa-Brody oil pipeline was built between the city of Odessa on the Black Sea and the city of Brody in the Lviv region, where it was connected to the Druzhba oil pipeline.

MOT Pivdenny

The operational length is 667 km, the design capacity is 14.5 million tons of oil per year.

It was supposed to transport Caspian and Kazakh oil bypassing the Turkish straits from the port of Pivdenny near Odesa to the refineries in Eastern and Central Europe and to Northern Europe through the port of Gdansk. The oil pipeline was built during 1996-2002. Construction cost – $ 453 million. It was assumed that subsequently a pipe would be laid from Brody to Polish Plock, which is already connected by an oil pipeline with Gdansk. However, from 2002 to 2004, the Odessa-Brody oil pipeline stood idle, since the Ukrainian government did not receive guarantees from oil companies operating in the Caspian Sea to load it with cargo. Russia sought to use this section in a reverse mode for the supply of Russian oil to the ports of the Mediterranean. On August 18th, 2004, Russia and Ukraine signed a long-term oil transit agreement, according to which oil from the Druzhba pipeline was delivered to the terminals of the Ukrainian port of Yuzhny.

MOT Pivdenny

During operation in reverse mode, Ukraine tried to change the direction of oil flows:

In 2005, Viktor Yushchenko, elected President of Ukraine, called the Odessa-Brody oil pipeline one of the country’s most successful energy projects and announced his intention to reorient it to supply Caspian oil to Europe. Yushchenko and Polish President Kwasniewski agreed to urgently complete the construction of an oil pipeline to Gdansk.

On March 5th, 2005, Yulia Tymoshenko announced her readiness to stop the reverse movement of Russian oil through the Odessa-Brody pipeline and to put Kazakh oil into the pipeline in the direction of Europe. On the same day, the Secretary of State of the President of Ukraine Oleksandr Zinchenko, following the results of negotiations with the Kazakh government in Astana, said that the negotiators had expressed interest in the construction of the Brody-Plock pipeline with a length of 490 km and a cost of $ 500 million. This route would allow Ukrainians to transport Central Asian oil to the refinery in Plock.

In 2005-2007, several governments changed in Ukraine and Poland, but these plans were never implemented.

MOT Pivdenny

In mid-2010, the reverse operation of the pipeline was terminated. In November of the same year, attempts began to pump Venezuelan and Azerbaijani oil to Belarus under a two-year contract. However, for economic reasons, instead of the planned 4 million tons per year in 2011, only 1 million tons were pumped. Since the end of 2011, supplies under this contract have been discontinued.

In 2011, a part of Ukrtransnafta was unable to pump a part of an experimental batch of oil purchased from Azerbaijan for an oil refinery in the Czech Republic. The official reason was the position of Slovakia. As a result, oil was processed on the territory of Ukraine with a loss of about UAH 400 million (USD 146 800).

At the end of 2013, the pipeline was prepared for the transportation of Russian oil in reverse mode.

On October 29th, 2013, at a meeting of shareholders of Sarmatia, representatives of the Polish company PERN Priyazn suspended further financing of the project. Since then, the pipeline has been idle. In March 2020, Ukraine, after a long break, resumed the operation of the oil pipeline, starting oil transit to Belarus. This happened after Russia refused to supply oil to a “friendly” country. The provision of services for the transportation of oil to the Republic of Belarus is carried out under an agreement between JSC Ukrtransnafta and BNK (UK) Limited (Great Britain), which is a subsidiary of CJSC Belarusian Oil Company.

BERTH NUMBER 3N

TERMINAL STEVEDORING AND CO (FORMER TRANSBUNKER-SOUTH)

Subsidiaries of the Russian Transbunker also continue to work actively in the ports of the Odessa region – Terminal Stevedoring and Co (former Transbunker-Yuzhny). The company leases a significant part of the area and capacities of the state port, in fact concentrating them in its hands: the enterprise is located on four land plots used on a lease basis with a total area of 5.6 hectares.

Production capacity: Terminal Capital Invest LLC is the owner of a bunkering base in the Marine Trade Port “Yuzhny” with a throughput capacity of 1 million tons of oil products per year, which is operated by Terminal Stevedoring and Co LLC. The total volume of tanks for one-time storage of fuel oil is -70 thousand cubic meters. Transshipment of oil products is carried out through its own berths № 5A and № 5B.

Berth № 5A was built in 2000 and has a length of 102.1 m and a draft of 7.2 m.

Berth № 5B was built in 2003 and has a length of 241.4 m and a draft of 11.3 m.

Terminal Stevedoring and Co LLC is part of the Transbunker group of companies.

According to official data, the heads of the Transbunker holding are Russian citizens Joseph Sandler and Sergei Pugachev. The main assets of the holding are listed in the Cypriot offshore companies: Transbunker Capital Ltd, Transbunker Management Ltd and the Russian Transbunker Holding Ltd. The offshore companies are run by the Swiss company Tanor SA. The Transbunker group of companies is engaged in the wholesale trade of oil and bunkering of vessels.

In 2019, the transshipment complex interested Ukrtransnafta. The company’s financial statements for 2018 included investments to buy out 100% of the complex’s corporate rights.

Terminal Stevedoring & Co

Development of the deepest water area in the country

At the moment, the port Pivdenny is the deepest ice-free port of the Azov-Black Sea basin. The maximum depth in the port is 19 meters. The port can accept vessels up to 300 meters in length with a draft of up to 18.5 m. This is the only Ukrainian port that can accept vessels of the Capesize and NEWCASTLE MAX types.

In the 2000s, the issue of dredging became actual in the ports of the Black Sea region.

Dredging works at the port began in 2012.

On June 22nd, 2014, from the berth № 6 of the coal-ore complex of the SE “Commercial Sea Port of Yuzhny”, the Capesize KANARIS set off on a voyage. For the first time, the vessel was loaded to full cargo capacity at the quay wall at a draft of 18.5 m with the iron ore concentrate of the Metinvest holding.

Draft of 18.5 meters was allowed in Yuzhny from June 21, 2014. The corresponding order was signed by the head of the seaport of Yuzhny administration, Maxim Shirokov.

Ukrainian port workers understand what an extraordinary event happened at their eyes. The implementation of a large-scale project for the reconstruction, deepening to 21 meters of the approach routes and water area of the Yuzhny port has been underway since the beginning of 2013 (first by the port, and after the adoption of the Law on ports in June 2013 by the Ukrainian Sea Ports Authority). This turned the largest port in Ukraine and the deepest one on the Black Sea. And, therefore, in one of the most competitive, where they began to enter and be processed until full draft at the capesize berths with a deadweight of up to 175 thousand tons.

In 2016, the Yuzhnensky branch of the State Enterprise ” Ukrainian Sea Ports Authority ” accepted the offer of Jan De Nul Ukraine LLC worth UAH 988.95 million (USD 36 425 919.83) for the reconstruction of the sea approach channel and inland water approaches to the deep-water berths of the port.

It was envisaged to carry out dredging works in the amount of 3.44 million cubic meters during transportation to sea dumps located 8.7 and 7.3 km from the port entrance. That is, the average cost of work would be UAH 287 (USD 10.57) / cubic meter.

This could be a record price for dredging in Ukraine. Previously, the record was 283 UAH (USD 10.42) per cubic meter – in 2015, Ligos UA received a contract at this price for dredging in the same Yuzhny port. The winner of the auction Jan De Nul Ukraine was registered in Odesa. Until 2015, its founders were Dredging End Maritime Management SA (Luxemburg) and Dredging End Contracting Rotterdam B.V. (Netherlands).

However, on the eve of the dredging tender, the owners and management of Jan De Nul Ukraine changed.

The founders include two Cypriot companies Havoret Investments Limited and Medit Consortium Dredging Company Limited. And Andrey Rozov was appointed director.

That time the tender didn’t take place.

In 2017, the Chinese company China Harbor Engineering Company Ltd. start of work on dredging in the water area of the Yuzhny seaport. On May 18th, 2017, the State Enterprise ” Ukrainian Sea Ports Authority ” signed a contract with CHEC to carry out dredging works in Yuzhny port. In accordance with the document, the contractor increased the depths of the approach channel from 16 to 19 m, created an operating water area with a depth of 16 m near berths 23-25. The project budget was UAH 1.065 billion (USD 39 227 063.67). In addition, at the same time, another contract was signed with China Harbor Engineering Company Ltd. for the reconstruction of the sea approach channel in Yuzhny. Under the terms of this contract, CHEC dredged the sea approach channel and the operating water area of berths № 5 and № 6 of Yuzhny seaport of from 19 m to 21 m, and also expanded the sea approach channel from 140 m to 210 m – 230 m. works amounted to 3.5 million cubic meters. meters. Cost – UAH 586 million (USD 21 584 093.25).

Berths 5 and 6

Demand creates supply

Two years ago, the Ukrainian Sea Ports Authority and the TIS Group of Companies signed a Memorandum of Understanding providing for the implementation of infrastructure projects in the seaport of Pivdenny on terms of co-financing.

It follows from the memorandum that dredging works on the internal access canals and in the operating water area of the port of Pivdenny are carried out according to a public-private partnership project that is unique for the maritime industry.

Thus, according to the document, dredging of the internal approach channel to berths 18–22 to 19 meters will be carried out by the USPA at the expense of port dues (money paid by ships entering the port).

In other words, a private stevedore attracts ships with modern terminals and depths capable of receiving large vessels; in turn, the USPA receives additional revenue in the form of port dues.

The deepening of the operating water area of these berths to 16-19 meters was carried out by the TIS group of companies at its own expense. After dredging the approach channel, the company, by means of the USPA, pledged to increase the volume of cargo handling by 10-15 million tons within ten years.

In 2018, the Port Council approved the “Plan-Scheme for the Development of the Pivdenny Seaport” developed by SE “CHERNOMORNIIPROEKT”.

“The development plan of the Pivdenny seaport provides for the implementation of 25 USPA investment projects jointly with state and private investors. The implementation of these projects will undoubtedly lead to a significant increase in the load on the infrastructure of railways and highways, energy, gas and water supply systems, which means that there is a need to carry out calculations for the gradual planned development and modernization of this infrastructure in sync with the implementation of investment projects. The preservation of about 10 thousand existing jobs and the creation of about 3.5 thousand new jobs depend on the efficient operation of the port and the successful launch of all planned projects,” said the head of the USPA Raivis Veckagans at that time.

On the basis of the above-mentioned Development Scheme for the onshore part of the port of Pivdenny, a feasibility study of the railway, automotive and energy infrastructure should be developed. In particular, a decision was made on the need to implement a feasibility study for the development of railway infrastructure in the sections from Chornomorska stations to Beregovaya, Khimicheskaya and Promyshlennaya. As part of measures aimed at increasing the level of communication between the administration of the seaport of Yuzhny, port operators, stevedoring companies, local authorities and scientific organizations, it was decided to create an electronic resource that will provide a sufficient level of information exchange on proposals, comments and additions to the main calculations and design solutions of Plan-scheme.

Currently, in the water area of the Pivdenny seaport, cargo is processed by the following port operators:

– SE MTP “Yuzhny” – iron ore concentrate (iron ore concentrate), pellets, coal, mineral construction materials, etc.

– Odessa Port Plant JSC – chemical bulk and liquid cargo.

– TIS-Fertilizers LLC – bulk chemical cargo.

– TIS-Grain LLC – grain cargo.

– TIS-Ore LLC – bulk cargo.

– TIS-Coal LLC – bulk cargo.

– TIS-Container Terminal LLC – general cargo, oil.

– M.V. Cargo LLC – grain cargo.

– Borivazh LLC – grain cargo.

– Delta Wilmar CIS LLC – vegetable oil.

– Risoil Yug LLC – vegetable oil.

– Olsids Black Sea LLC – vegetable oil.

– Seaside (Ukraine) DС – grain cargo.

– Terminal Stevedoring and K LLC – oil products.

– Ukrtransnafta (OOT Pivdenny) PJSC – crude oil.

Environmental Safety

Yuzhny is a port with increased danger, due to the processing of liquefied gas and chemical goods, in particular, ammonia. However, due to the special attention to safety issues, over the years of the enterprise’s existence, it did not pose any serious threat either to the city of Yuzhny, or to Odesa, located only 50 km from the port. Despite the large volumes of cargo transshipment, as well as their high chemical hazard, the environmental situation in the port (Adjalyk estuary) remains one of the best in the world. Various species of birds nest in the water area, including swans and gray herons, schools of fish walk and the Black Sea bottlenose dolphins come regularly.