Trolls and blue marlins: how vessels transport unique cargo

USM tells how a 255-year-old mansion was transported on a barge, how ten tugboats hauled the world’s heaviest drilling platform, whether one vessel is capable of transporting an aircraft carrier, and how Ukrainian ports handle oversized cargo.

Float the old mansion across the bay

In 2019, American Christian Neely bought the 255-year-old Galloway Manor. The house was built in 1764 and was located in Easton, Minnesota, but its new buyer decided that the mansion needed to be located in a “more suitable location.”

Neely had a plan in his head. To do this, he decided to put the entire house together, drive it six miles through Easton, load it on a barge, and then sail 50 miles across the Chesapeake Bay to a new location in Queenstown, Maryland.

And the plan worked – the house was removed from the foundation, loaded onto a barge and shipped to the place of a new registration right along the bay. Despite its venerable age, the mansion endured the journey with dignity, however, after transportation it had to be slightly restored.

How ten tugs pulled the troll

Offshore oil and gas production platforms, as well as drilling platforms are not such a rare oversized cargo. But the scale of transportation of these giants is breathtaking. At least because the platforms are among the largest structures in the world, and most of them are usually hidden from view under water.

But there is also a unique case – the Troll-A gas production platform, a giant among all giants. It is the highest structure that has ever moved to a different position relatively to the surface of the Earth. The platform is one of the highest and most complex technical projects in history.

The Troll Oil Platform was built in Norway for Shell Norske in July 1991. When all the preparatory work was completed, the platform began to be towed to the gas field. The ten largest tugboats in the world covered 278 km with the platform in a week.

Despite the fact that the structure is very massive, its thin pillars are relatively resistant to sea waves and currents. When the platform arrived, the foundation cylinders were gradually filled with water to sink the structure to the bottom of the sea. After the lowering, the installation was deepened by another 36 meters for greater stability.

On October 1st, 1996, gas began flowing from the Troll-A platform to the Norwegian coast. It is assumed that gas production will continue for another 55 years and will amount to 1.3 billion cubic meters in total.

Submersible vessels and yacht transportation by vessel

Every year, Dockwise Yacht Transport reminds the world that its submersible vessels are among the most unusual in the world, and the cargo transported by the company is expensive and unique.

But it’s better to start with a legend. Once, in unknown years, due to another depression in the oil industry, the number of orders for the transportation of out-of-gauge and oversized cargo decreased significantly. Then the managers of the shipping company (in the future, the same Dockwise Yacht Transport) proposed to conduct a survey among their employees with one question: what can be done to make their vessels profitable? There were many proposals, but one of them was decisive: the transportation of yachts, mainly from the Mediterranean Sea to various ports in the world.

The idea is that yachts cannot cover long distances across the ocean for several reasons. Firstly, the wave height can reach 12 meters, secondly, the yacht does not have enough fuel for a long voyage, and thirdly, engine wear is relatively small. It turns out that using the services of a submersible vessel for the transportation of yachts is more economical, safer and faster.

Today, the shipping company has several vessels converted exclusively for the transportation of yachts. Moreover, for an additional fee, interested owners can go for a sea cruise with their yachts.

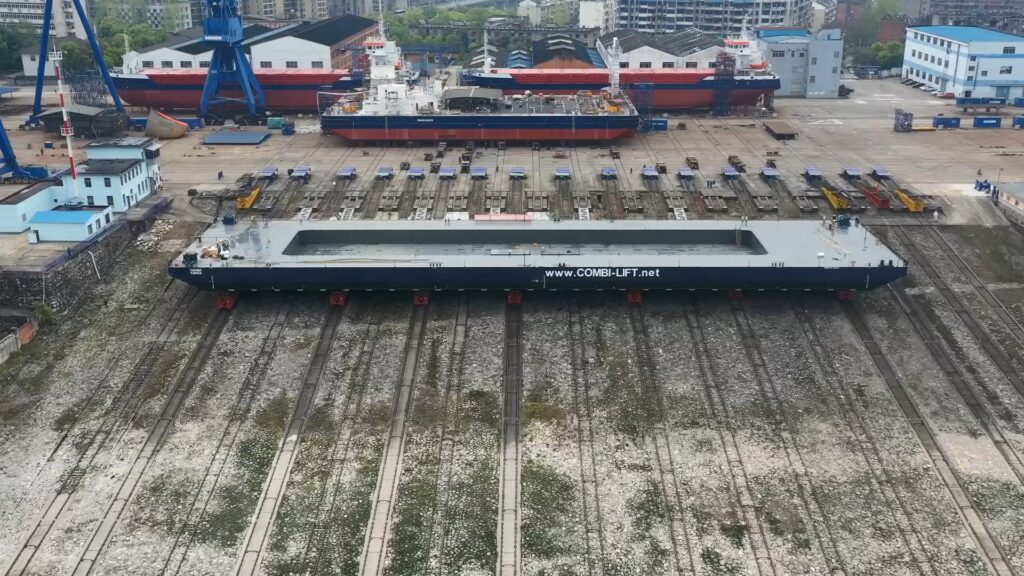

Special barge for the transportation of columns to the Amur Gas Chemical Complex in the Russian Federation

The Amur Gas Chemical Complex is the largest enterprise for the production of polyethylene and polypropylene in the Russian Federation. And in May 2021, a logistics operation began to deliver the most bulky equipment of the Amur Gas Chemical Complex – a pyrogas water wash column, designed for a pyrolysis unit, weighing 1540 tons and with a length of 80.6 meters.

To deliver the equipment, a special barge “Tomsk” was built at the Damen shipyard in China. It is designed so that when transporting heavy columns, its draft is only 1 meter. A low draft is necessary for smooth passage along the fairway of the shallow Zeya River in the Amur Region to the discharge berth.

The column loading operation was carried out in the South Korean port of Masan. With the help of two floating cranes, the column was loaded onto a barge. The barge itself was on the deck of an submersible vessel.

It took about 12 hours to load and secure the equipment. Then the vessel sailed to the Russian port of De-Kastri, where its deck was submerged again, after which the barge with the column was pushed out into the water.

There was a problem with this cargo on Zeya, though. The barge with the pipe could not pass under the road bridge due to the high water level in the river and got stuck. A little later, the vessel was pulled out of the trap and towed to the area of the village of Zazeisky. There the vessel waited for the water to go in the river down.

A vessel that can carry 22 barges at the same time

“Blue Marlin”, an submersible heavy-lift vessel, is designed for the transportation of heavy and oversized cargo. It is capable of withstanding a load of up to 75 thousand tons, so it can take on board other vessels and oil platforms.

When the US Navy needed to transport the attacked destroyer USS Cole to America, they chartered the Blue Marlin. In addition, the Australian Navy transported a Spanish-built aircraft carrier also with the help of the Blue Marlin.

The Blue Marlin’s deck area is the equivalent of two soccer fields. The vessel moves at an average speed of 13 knots, is equipped with a giant diesel engine with a capacity of 17 thousand HP, and is serviced by a crew of 24 people.

Another of the Blue Marlin cases is the transportation of 22 barges weighing 3 thousand tons each at a time from Korea to Rotterdam. The barges weigh a total of 60 thousand tons. For loading super-heavy cargo, the vessel is submerged 13 meters into the water, which makes it possible to transport almost any cargo by water to the deck. Diving is carried out by filling ballast tanks with water.

Blue Marlin has moved many objects over the years. For example, in July 2005, he transported an entire refinery on board. In November of that year, he delivered a giant maritime radar to Pearl Harbor, covering about 15 thousand miles. In 2007, transported two large rigs, Rowan Gorilla VI and Global Santa Fe Galaxy II, from Halifax Port to the North Sea. In 2012, Blue Marlin delivered the hull of the HMAS Canberra to Williamstown, Victoria.

Examples of oversized cargo in Ukraine

In Ukraine, examples of out-of-gauge cargo, although not striking in scale, but their regularity is redeeming. Almost every Ukrainian seaport handles oversized cargo.

For example, in the port of Pivdenny, parts of huge wind farms are handled several times a year. So, at the end of February, another vessel with blades was processed in the port: the weight of one blade was 23 tons, and the length was 72.4 meters. The cargo was transshipped to SE “CSP “Yuzhny”. Before discharging such equipment, roads were expanded on the territory of Yuzhny, warehouses were prepared and a technology for handling oversized cargo was developed.

The port of Reni accepts a similar cargo. In the fall of 2020, the components of the future Dniester wind-power station, which is planned to be built in the Odesa region, arrived at the port of Reni along the Danube River. Note, before starting the process of transportation of parts of the wind farm, the carrier of parts of the wind-power station has developed a special transport route. During the check of the route, significant damage was revealed to five bridges and, after the approval of the project, the carrier carried out work on strengthening the bridges at his own expense.

Several times a year, out-of-gauge and unusual cargo is accepted by the port of Odesa. In December 2020, three trucks with export equipment manufactured by Zaporozhkran CJSC entered the port of Odesa with escort. The components of the travelling cranes were fixed on the trailers with steel cables.

The specific cargo was delivered in March of this year by the vessels of the Ukrainian Danube Shipping Company. The motor vessel “Znamenka” and the pontoon TMI-4 transported structures intended for the construction of a bridge in Romania. A pontoon with sections limited visibility during transportation, the crew worked in conditions of rising water and strong winds. According to the captain of Znamenka, in Brail, the pontoon was lifted onto the factory slipway, where special steel structures were prepared, to which parts of the bridge were to be attached. After loading the TMI with the two sections of the bridge, the pontoon was taken to Galatz.

In 2021, an interesting oversized cargo was also transshipped in the port of Chornomorsk. In March, the vessel NAZ1 arrived here from Turkey with a consignment of out-of-gauge cargo (production line) for the Roshen Confectionery Corporation. Due to the large size of cargo spaces (LxWxH – 4.97 * 4.97 * 4.69m), the process of removing the equipment was preceded by a thorough preparation. The transportation route was fully surveyed, all possible obstacles from the gateway of the port to the place of delivery were measured, and alternative passages of the limiting sections were outlined.

In the port of Chornomorsk, more precisely, on the road of the port, oversized cargo was also transshipped. For example, in May the heavyweight vessel Zhen Hua 33 arrived at the anchorage at the port of Chornomorsk. Zhen Hua 33 should have taken on board the dredging fleet of China Harbor Engineering Company Ltd., which carried out dredging works in the ports of Chornomorsk and Pivdenny. All operations were carried out at the anchorage without calling at the port. As a result, Zhen Hua 33 took on board 4 units of dredging equipment.

“The departure of the vessel was constantly shifted to later dates due to weather conditions. Rain and strong winds, which have been frequent in recent days, made it difficult to complete the fastening of the dredging vessels on the deck of Zhen Hua 33. One way or another, all the securing efforts were completed, after which a specialist was brought aboard the vessel, who conducted an NDT survey (cargo securing reliability). After departure from port of Chornomorsk on May 22nd, the vessel headed for Tanzania,” told USM Dmitry Gotka, vessel`s agent of Stark Shipping LLC.

Recently, Ukrainian ports are increasingly handling out-of-gauge cargo. Although this causes additional difficulties in handling such cargo, the examples described above prove that Ukrainian ports are ready for such challenges. Of course, we do not transport oil platforms, but it is nice to know that every year in ports there are at least a couple of interesting examples of oversized cargo handling.

Ruslan Soroka.